Paper

Logistics in the paper industry involves the planning, coordination, and execution of activities related to the transportation, storage, and distribution of various paper products. Here’s an overview of key aspects in the logistics process for the paper sector:

Raw Material Sourcing:

- Coordinate the transportation of raw materials such as wood pulp or recycled paper to paper mills.

- Ensure a steady supply of raw materials to meet production demands.

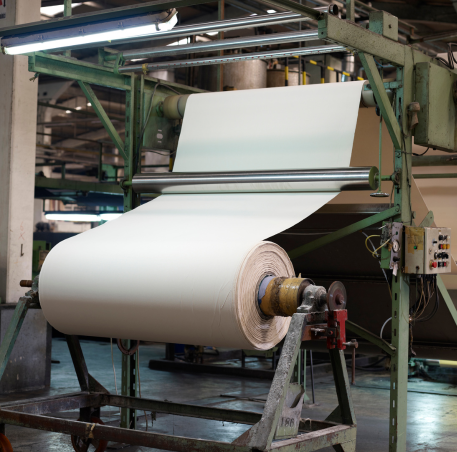

Paper Manufacturing:

- Transport processed paper rolls or sheets from manufacturing plants to distribution centers.

- Manage the movement of chemicals and other materials used in the paper production process.

Packaging:

- Proper packaging is essential to protect paper products during transportation.

- Use suitable materials to prevent damage from moisture, tearing, or other potential hazards.

Transportation:

- Choose suitable transportation modes such as trucks, trains, ships, or air freight based on the type of paper, distance, and infrastructure available.

- Consider factors like cost, transit time, and the fragility of the paper products.

Warehousing:

- Store paper rolls or sheets in warehouses before distribution.

- Warehousing may involve specialized facilities with considerations for temperature, humidity, and security.

Inventory Management:

- Implement efficient inventory management systems to monitor stock levels and prevent stockouts.

- Real-time tracking helps optimize inventory and streamline supply chain operations.

Quality Control:

- Conduct quality control checks at various stages, ensuring that the paper products meet specified standards.

- Quality assurance is crucial for maintaining customer satisfaction and regulatory compliance.

Documentation and Compliance:

- Prepare and manage shipping documents, customs declarations, and compliance with international trade regulations.

- Ensure compliance with environmental and safety regulations related to the transportation of paper products.

Supply Chain Visibility:

- Implement technologies for supply chain visibility, such as tracking systems and data analytics, to enhance transparency and efficiency.

Collaboration and Communication:

- Foster collaboration between paper manufacturers, logistics providers, and end-users to optimize supply chain efficiency.

- Clear communication is essential for managing expectations and addressing any challenges that may arise.

Last-Mile Delivery:

- Plan for the efficient last-mile delivery of paper products to end-users, retailers, or printing facilities.

- Consider local transportation methods and regulations for final distribution.

Technology Integration:

- Utilize technologies like GPS tracking, RFID, and integrated logistics management systems for enhanced efficiency and visibility.

Sustainability Practices:

- Explore sustainable logistics practices, such as optimizing transportation routes to reduce emissions or adopting eco-friendly packaging materials.

The paper industry’s logistics process is diverse, covering a wide range of products and involving various transportation modes. Efficient logistics are crucial for ensuring the availability of paper products while minimizing costs and environmental impact.